Friction Stir Welding, in which metals are joined via mechanical pressure – it's the same technique that has been used for experimental steel/aluminum spot welds in the past. As Honda explains it, “This technology generates a new and stable metallic bonding between steel and aluminum by moving a rotating tool on the top of the aluminum which is lapped over the steel with high pressure.” The welds that result are reportedly as strong or stronger than those made using regular Metal Inert Gas welding.

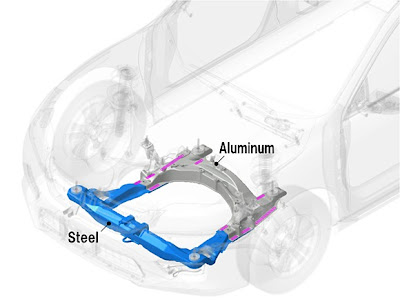

Steel/aluminum subframes built with the new technique are said to be 25 percent lighter than those made entirely out of steel, which should translate into improved fuel economy. The process also made it possible to alter the structure of the subframe, so that the mounting point for the suspension could be relocated – this change has reportedly increased the rigidity of the mounting point by 20 percent, and thereby improved the car’s dynamic performance.

Additionally, the new process uses about half the amount of electricity as Metal Inert Gas welding, and the machinery it requires isn’t as large as that traditionally used for Friction Stir Welding – in fact, it can be attached to an industrial robot. The technique can also be used for aluminum-to-aluminum welding, without any hardware changes.

A new non-destructive inspection system, incorporating an infra-red camera and a laser, is used to check all of the steel/aluminum welds.

No comments:

Post a Comment